Manufacturing Process

Flexibility, ingeniousness and expertise at the service of customers' needs

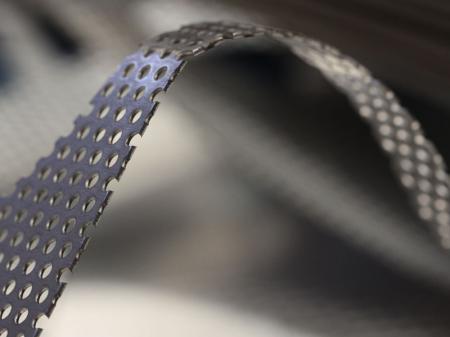

The manufacturing process at Metal Design is the result of the experience accrued over the years in the sector of sheet metal processing and metalworking: the production stages and methods have been analysed and implemented with the aim of ensuring the utmost flexibility and reliability in adapting to any need for specific sectors.

Metal Design's competitive edge is ensured by the extreme flexibility it has developed, which allows us to produce either prototypes or small or large series with optimal quality, times and costs: we always combine high product quality, quick manufacturing times and customisation to cater for each customer's specific needs.

The manufacturing process of any of our metal processing work starts with an inspection of the raw material, followed by the various steps of the industrial cycle, from first manufacturing processes to the last finishes, always in line with strict quality standards.

The metal items can be supplied according to the various customer requirements – from an unfinished state to a fully finished product – as we have developed partnerships with the best companies in the metal treatment and metal surface finish sectors (cleaning, electroplating, anodising, painting, etc.).

In production we rely on a valuable wealth of human resources provided by individual operators in terms of professionalism, experience, motivation and ingeniousness, which provides a fundamental contribution to enriching customer relations with an invaluable added value.